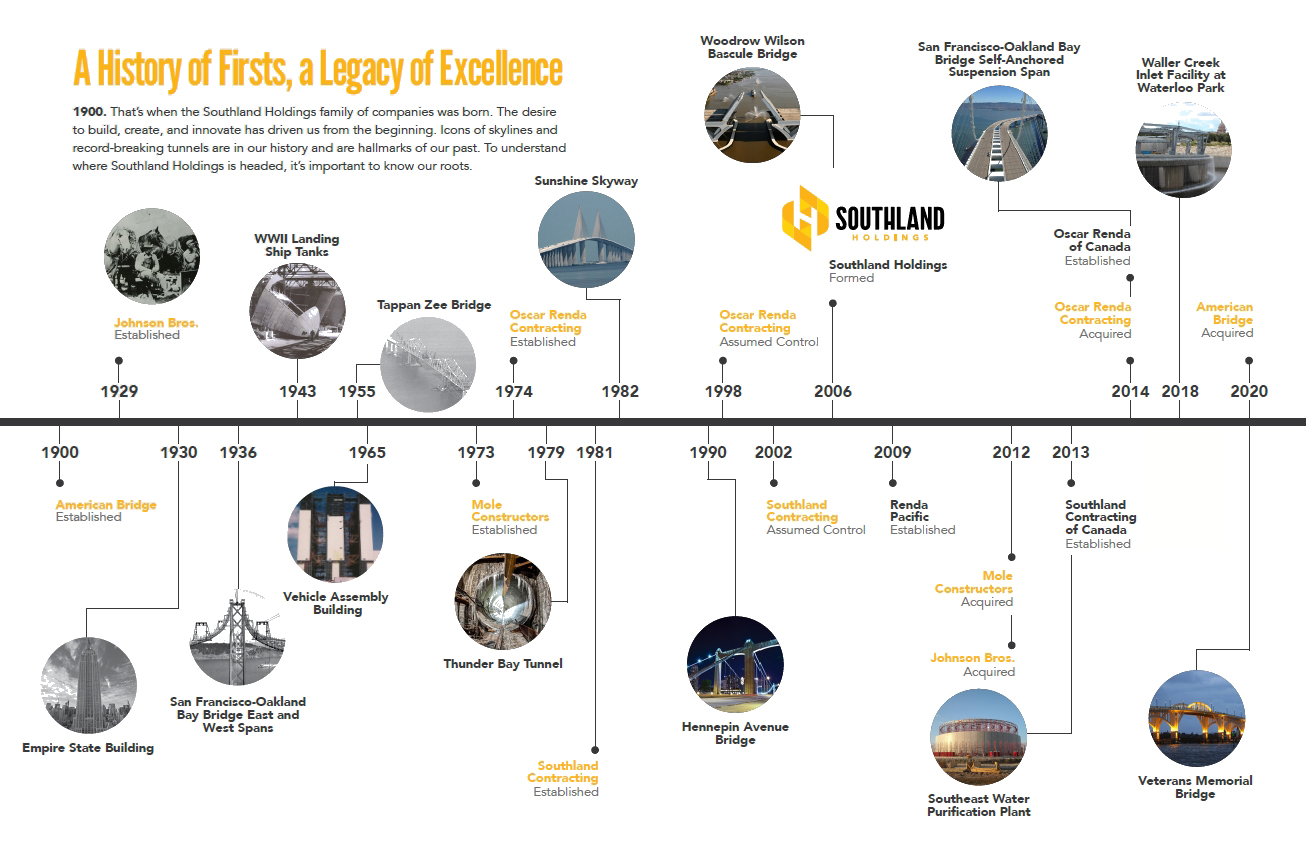

History

American Bridge Company was founded in 1900 as a JP Morgan-engineered merger of 28 bridge and steel companies. One year later, American Bridge began construction of a new fabricating and manufacturing facility in Ambridge, Pennsylvania – which became the largest steel fabrication plant in the world. Over the next twelve decades, the company built some of the world’s most recognizable bridges, buildings, and complex steel erection projects. In 2020, American Bridge became part of the Southland Holdings family of companies.

American Bridge excels at engineering and self-performing construction means and methods, as well as executing never before seen techniques in the field. A collaborative approach between the in-house engineering department and field teams yields approaches that are safer and more efficient, delivering challenging bridge, marine, and complex structure projects for our clients.

Bridge Construction: Bridge building has always been at the core of our culture, focus, and activity. The types of bridges we construct include cable-supported, movable, arch, railroad, girder, truss, utility, and pedestrian, bicycle, and trail.

Complex Rehabilitation: American Bridge specializes in complex rehabilitation and demolition projects that require extensive engineering means and methods. We focus on innovative ways to reduce impacts on the local communities and traveling public, keeping them safe and moving while we work.

Marine Construction: American Bridge has undertaken major marine construction projects in the United States, Caribbean, and Central and South America. We are specialists in pile driving, pier and wharf construction, cofferdams, drilled shaft installation, steel sheet pile structures, and tieback systems.

Special Projects: American Bridge retains a strong interest in unique projects that are constantly proving our ability to solve tough construction challenges. From vertical structures to observation wheels and convention centers, complex steel erection remains a core focus.

Founded by Walter D. Johnson in 1929 as Johnson Construction, Johnson Bros. Corporation has been a leader in the infrastructure industry with more than 90 years of experience specializing in bridge, highway, marine, industrial, and emergency construction services for both public and private clients. In 2012, Jonhson Bros. joined the Southland Holdings family of companies.

Over the decades, Johnson Bros. has distinguished itself by staying on the cutting edge of construction technology and methodology. From barges and temporary work trestles to heavy crane picks and complex maneuvers, Johnson Bros. tackles signature bridge and marine-based projects. Johnson Bros. was the first contractor in the United States to use the incremental launching technique to deliver the Belleair Beach Causeway Bridge and continues to pioneer innovative construction solutions for its clients. Johnson Bros.’ internal engineering department provides custom design solutions to keep the projects safe and on budget.

Johnson Bros. capabilities span the infrastructure construction industry, from signature bridges, marine crossings, and highway interchanges to ports and docks, airports, railroad facilities, and dams and reservoirs.

Established by Oscar Renda in 1974, after his immigration to the United States with his brother Rudolph, Oscar Renda Contracting (ORC) delivers water pipeline and facilities projects across North America. As reliable water supply systems become increasingly critical, ORC’s wide range of self-performance capabilities help clients deliver essential projects that sustain communities, industries, and infrastructure.

ORC has a nationwide presence and serves the water/wastewater conveyance and treatment, transportation, tunneling, and marine construction markets. With over four million linear feet of pipeline installed, ORC is known for safety, value engineering, and performance. From underground grids to facilities on the cutting edge of technology, ORC’s work delivers reliable connections and conveyance solutions for public and private clients.

Born in 1981 from the efforts of mechanical genius Charlie Griffith, Southland Contracting established itself as a leader in tunneling. Seeing the advantages of having its own in-house tunneling company, the rebranded Southland Contracting, Inc. was added to the Southland Holdings family of companies. Since that time, it has kept its place as a force in the tunneling industry and has built projects that span more than 5,000 miles across the globe — from water conveyance projects in Hawaii, to reservoir outlets in New York State and outfall tunnels in Lake Ontario.

Today, Southland Contracting is an expert in all forms of trenchless techniques and technologies. Using hard rock and earth pressure balance tunnel boring machines, horizontal directional drilling machines, shield tunneling, Roadheader, NATM, pipe jacking and drill and blast methods, Southland Contracting has excavated tunnels and shafts in a variety of geotechnical conditions

From the hardest of rock and stone deposits to soft soils and water-saturated formations 200 feet below sea level, there isn’t a tunneling configuration that Southland Contracting hasn’t been able to conquer.

Founded as a family-run company by Victor Scaravilli in 1973, Mole Constructors, Inc. specializes in tunneling throughout the United States and Canada. By 2010, Mole was already recognized as a global leader in the underground industry, contributing new and innovative approaches to

various engineering challenges. The company completed projects with more than 140,000 total linear feet of tunnel.

It was this family-based, innovative, and successful approach that drew the attention of Southland Holdings. Mole was acquired in 2012 and added to the growing heavy civil construction giant. Since then, Southland Holdings has utilized the capabilities of the renamed Mole Constructors to complete more than 1 million linear feet in tunneling projects, making the company a recognized worldwide leader in tunneling.

Today, Mole Constructors provides advanced tunneling expertise and professional excellence to fulfill a myriad of projects – from hand-mining methods to the use of the record-breaking Big Tex, a tunnel boring machine with a 38-foot diameter face.