Archives

American Bridge Landing Ship Tanks (LSTs) – Featured Archive

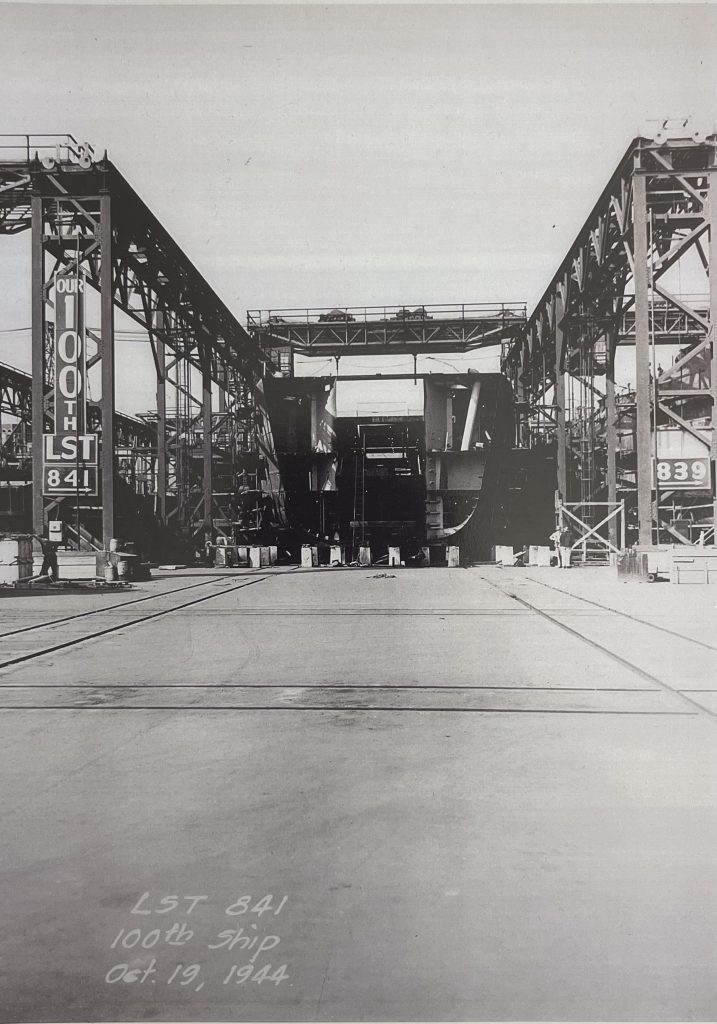

American Bridge Landing Ship Tanks (LSTs) – Featured Archive https://www.southlandholdings.com/wp-content/uploads/2024/05/lst-262-1.jpg 960 794 Southland Holdings Southland Holdings https://www.southlandholdings.com/wp-content/uploads/2024/05/lst-262-1.jpgFrom 1941-1945, 100% of American Bridge’s capacity was utilized for National Defense projects. During the war, the US Government needed American Bridge’s world class manufacturing and engineering teams to assist in wartime preparations. American Bridge manufactured 199 LST’s as well as four Aviation Repair Vessels, major components for 11 Essex Class Aircraft Carriers, one Super-aircraft Carrier, and 31 Auxiliary Converted Aircraft Carriers, 77 C Type Cargo Ships, four Tankers, 20 Cargo Lighters, and 348 Knock-down Barges.

Other war related projects included the construction of a grassroots steelmaking facility in Geneva, Utah; major Aluminum manufacturing facilities in Tennessee, and steel mill expansions in Pittsburgh. American Bridge also built militarily strategic bridges including the Harry Truman vertical lift rail bridge in Kansas City; the Terminal Island rail bridge in Long Beach; and the Liard River Suspension Bridge on the Alaska Highway in British Columbia – all still in use today. The most famous of AB’s work was surely the LSTs (Landing Ship Tanks), which assisted on D-Day among many other military operations.

The LSTs

Landing Ship Tanks (LSTs) were crucial amphibious vessels designed during World War II to support large-scale allied invasions. Winston Churchill had asked the Navy to create an amphibious ship which could transport tanks and vehicles to assist in large scale invasions. The man who is accredited with the design of the LST is John C. Neidermair, a Naval Architect who helped create many of the Naval Ships we know today. These ships were capable of carrying tanks, vehicles, cargo, and troops directly onto shore without the need for docks or piers, which was essential for operations in the European and Pacific theaters. LSTs were characterized by their large, flat-bottomed hulls, bow doors, and ramp, allowing them to beach themselves and quickly offload their cargo. Their design facilitated the rapid deployment of armored units and infantry, making them instrumental in operations like D-Day in Normandy and island-hopping campaigns in the Pacific.

Constructed primarily in the United States, LSTs were a testament to the Allies’ industrial capacity and innovation. Over 1,000 LSTs were built, and their versatility extended beyond just transporting vehicles and troops; they also served as makeshift hospitals, repair facilities, and supply ships. The ability of LSTs to deliver heavy equipment directly onto enemy shores significantly boosted the Allies’ operational capabilities, contributing to the success of numerous amphibious assaults. Post-war, many LSTs were repurposed for civilian use, demonstrating their robust and adaptable design.

Among the many ships, LST-266, known as USS Benzie County (named for a location in Michigan), earned two battle stars for service. USS Benzie County was just one of 199 LSTs that AB manufactured between 1941 and 1945 at our original workshop in Ambridge, PA. The LSTs were a crucial part of the USA and British military capabilities during oversea invasions in WWII. Another notable ship was LST-262. The ship earned 2 battle stars for its service in World War II servicing in Europe, Africa, and the Middle East. The image below shows LST-262 during the invasion of Normandy, also known as D-Day.

Manufacturing

The manufacturing of Landing Ship Tanks (LSTs) during World War II was a remarkable achievement of industrial engineering and mass production. The United States spearheaded the production of these vessels, recognizing the strategic necessity of having a ship capable of delivering heavy equipment and troops directly onto hostile shores. The design process began with a British request for such a vessel in 1941, leading to the creation of a collaborative design team.

The construction of LSTs took place mainly in inland shipyards located along river systems like the Ohio and Mississippi Rivers in order to maximize production capacity. Prefabrication played a crucial role in their rapid assembly. Components were manufactured separately and then transported to shipyards for final assembly, a process that significantly reduced construction time. The first LST, LST-1, was launched in October 1942. Standardization and modular construction allowed for the efficient production of over 1,000 LSTs by war’s end.

For American Bridge, the crews began assembling the LSTs in the Employee Gardens south of the AB Plant in Leetsdale, PA. At the peak of the operation, nearly 13,000 people were employed to help build these massive ships. Workers at these shipyards, including many women and inexperienced laborers, were trained rapidly to meet the high demand, showcasing the flexibility and scalability of American industrial capabilities. The crews worked 364 days a year, only taking off Christmas Day. When completed the ships stood 6 stories high and were over 100 yards long. The robust and versatile nature of LSTs, combined with the efficient manufacturing process, made them indispensable assets in the Allies’ amphibious warfare strategy.

- Posted In:

- Archives