Archives

A History of Manufacturing at American Bridge Company

A History of Manufacturing at American Bridge Company https://www.southlandholdings.com/wp-content/uploads/2024/05/Building-of-the-Mighty-Mac-2.jpg 960 686 Southland Holdings Southland Holdings https://www.southlandholdings.com/wp-content/uploads/2024/05/Building-of-the-Mighty-Mac-2.jpgThe roots of American Bridge Company trace back to a merger orchestrated by J.P. Morgan in 1900, which brought together 28 steel companies. By April 1, 1901, American Bridge had become a subsidiary of the United States Steel Company, following another move by Morgan, and was formally incorporated in Delaware. Post-merger, the company embarked on a comprehensive program aimed at both constructing and modernizing its facilities. This endeavor entailed shutting down some plants while upgrading others. Moreover, a new fabricating and manufacturing facility was built in southwestern Pennsylvania, completed in 1903, which became the largest of its kind worldwide. This facility also birthed a surrounding town, eventually named Ambridge, combining “American” and “Bridge.”

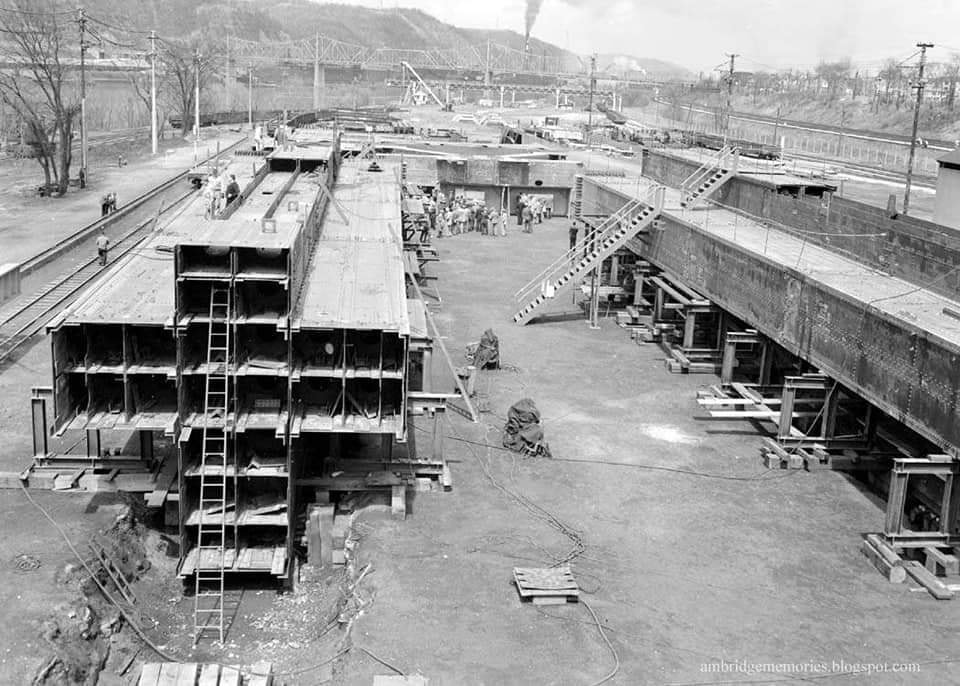

With substantial resources at its disposal, American Bridge emerged as a pioneer in fabricating and erecting various complex structures. It spearheaded the utilization of steel as a construction material, innovating fabrication and construction methods that enabled widespread use in buildings, bridges, vessels, and other applications. The town and the steel industry reached their zenith in the early 1940s, redirecting efforts to support the war. American Bridge, for instance, transitioned from bridge construction to building LST ships for the U.S. Navy and Coast Guard.

The impact of American Bridge’s legacy is evident today across the nation, from iconic landmarks like the Oakland Bay Bridge in San Francisco to the historic Brooklyn Bridge in New York. The company’s influence extended far beyond American borders, undertaking projects both nationally and internationally.

1900 to 1930

In 1915, the Ambridge Plant fabricated the Fair-Body portion of the hulls of eight sea-going tankers for the Chester Shipbuilding Company of Chester, Pennsylvania. This was the first time that a bridge and structural steel fabricating shop had used bridge-shop methods in the fabrication of hull steel for seagoing vessels as against the usual “cut and fit” methods prior to that time.

American Bridge completed the Hell Gate Arch Bridge in 1916. At the time of construction, it was the longest arch bridge in the world, and is still one of the heaviest.

Other notable projects in this decade include the Kentucky River High Bridge in Jessamine County, Kentucky; 81 railroad bridges for the Philippines Railroad System; the Atbara River Bridge in Sudan; the Manchester Bridge in Pittsburgh; six movable bridges for the Panama Canal Authority (used as emergency dams); the Columbia River Bridge at Vancouver, WA (now carrying I-5); the Union Pacific Railroad bridge over the Missouri River at Omaha, and the Metropolis railroad bridge over the Ohio River in Illinois, now owned by Canadian National Railway.

Between 1926 and 1928, American Bridge erected and fabricated the well-known Roberto Clemente Bridge (6th Street), Andy Warhol Bridge (7th Street), and Rachel Carson Bridge (9th Street) in Downtown Pittsburgh. Also known as “The Three Sisters,” American Bridge used an innovative approach to turn the eyebar catenary/deck girder system temporarily into a truss by adding a diagonal to enable erection by balance cantilever and avoiding falsework in the river. These nearly identical, self-anchored, eye-bar suspension bridges are familiar landmarks when overlooking the Pittsburgh skyline.

In 1929, American Bridge began airspinning cable with the construction of the Mid-Hudson Bridge in Poughkeepsie, NY. American Bridge fabricated and erected the towers, stiffening truss, cables, and roadway deck for this suspension bridge, requiring 13,275 tons of structural steel and 2,200 tons of cable. This began a long history of suspension bridge cable erection for American Bridge that continues to this day. To date, American Bridge has airspun well over half a million miles of suspension cable.

1930 to 1940

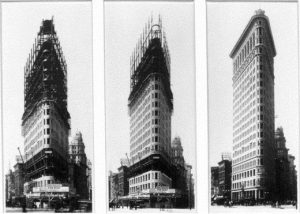

By 1938, American Bridge had furnished and erected bridges in 69 foreign countries and overseas US territories. American Bridge was involved in the fabrication and erection of the Empire State Building, an 86-story office building that was the tallest in the world when completed in 1930.

By 1938, American Bridge had furnished and erected bridges in 69 foreign countries and overseas US territories. American Bridge was involved in the fabrication and erection of the Empire State Building, an 86-story office building that was the tallest in the world when completed in 1930.

American Bridge completed the Bayonne Bridge in 1931, the longest arch superstructure in the world at the time. Soon after, American Bridge was chosen as the General Contractor for the East and West Bay portions of the Original San Francisco-Oakland Bridge. The San Francisco-Oakland Bay Bridge Project was completed in November 1936. That same year, the Virginia Bridge & Iron Company of Roanoke, Virginia, operating plants in Roanoke, Memphis, and Birmingham were acquired by American Bridge.

1940 to 1950

From 1941-1945, 100% of American Bridge’s capacity was utilized for National Defense projects. American Bridge manufactured 199 LST’s as well as four Aviation Repair Vessels, major components for 11 Essex Class Aircraft Carriers, one Super-aircraft Carrier, and 31 Auxiliary Converted Aircraft Carriers, 77 C Type Cargo Ships, four Tankers, 20 Cargo Lighters, and 348 Knock-down Barges.

Other war related projects included the construction of a grassroots steelmaking facility in Geneva, Utah; major Aluminum manufacturing facilities in Tennessee, and steel mill expansions in Pittsburgh. American Bridge also built militarily strategic bridges including the Harry Truman vertical lift rail bridge in Kansas City; the Terminal Island rail bridge in Long Beach; and the Liard River Suspension Bridge on the Alaska Highway in British Columbia – all still in use today.

1950 to 1960

American Bridge was prime superstructure contractor for the original Tappan Zee Bridge crossing the Hudson River above New York City. Although initial plans for the bridge were developed in the 1920s, construction did not commence until March of 1952. Construction was completed in 1955.

In 1957, American Bridge fabricated and erected the entire 47 span superstructure for the Straits of Mackinac Bridge. The 18,343-foot-long bridge remains one of the longest total suspended spans in the world. It was elected to be a National Historic Civil Engineering Landmark on August 12, 2010, by the American Society of Civil Engineers.

1960 to 1970

In this decade, American Bridge constructed Launch complexes 40-41 at Kennedy Space Center; the Norad Combat Operations Center in Colorado Springs; over 600 Minuteman Missile sites throughout Wyoming, Missouri, North Dakota, and Montana, and the Space Propulsion Facility at NASA Lewis Research Center in Sandusky, Ohio. The company continues to be active in this field today, with more recent projects including the Aeropropulsion Systems Test Facility at Tullahoma, Tennessee, numerous launch and processing facilities at Vandenberg Air Force Base, California, and Complex 17B at Cape Canaveral Air Force Station, Florida.

American Bridge has had a long history with the US Space Program; constructing wind tunnels, lab buildings, launch complexes, and rocket assembly buildings. In 1964, American Bridge completed the superstructure for the Vehicle Assembly Building at Kennedy Space Center. At 3.7 million cubic meters, this building remains one of the largest in the world.

In 1964, American Bridge fabricated and erected the Chicago Civic Center Building in Chicago, Illinois. The 31 story office building features COR-TEN steel which is weathering steel designed to form a rust-like appearance and eliminate the need for painting.

Three years later, AB fabricated and erected Chicago’s Picasso, a 50-foot-high sculpture to the design of Pablo Picasso. Located in the Plaza at the Chicago Civic Center, this special structure has a total weight of 162 tons.

1970 to 1980

American Bridge started building the William Preston Lane, Jr. Chesapeake Bay Bridge in 1970 and finished it in just three years. The bridge has 32 spans and is 14,500 feet long. It includes a main span suspension bridge that’s 1,600 feet long. American Bridge made the main suspension cables using prefabricated wires in Philadelphia.

In 1973, American Bridge worked on the Sears Tower in Chicago (now called the Willis Tower), fabricating and putting up 78,000 tons of steel. It’s still one of the tallest buildings in the U.S.

That same year, American Bridge began building the New River Gorge Bridge in West Virginia. It’s the longest deck arch bridge in the western hemisphere, with a length of 1,700 feet from end to end and 3,030 feet overall. The bridge sits about 900 feet above the New River, making it one of the highest in the world. American Bridge faced challenges like designing a cableway to lift the arch segments, each weighing 100 tons, and creating a tieback system to support the unfinished arch arms, with a capacity of 50,250 kips.

1980 to 2000

In partnership with Morrison Knudsen Corp, American Bridge served as the main contractor for two major projects. First, they constructed a 5.3-mile monorail connecting the Magic Kingdom and EPCOT theme parks. They built precast concrete beams and piers, installed steel piles, poured concrete foundations, assembled the monorail track, and powered it. The monorail includes both double and single beamways.

Additionally, in collaboration with Morrison Knudsen Corp and Pascen Construction, American Bridge oversaw the construction of the all-concrete, 8,858-foot Sunshine Skyway high-level bridge in Tampa, Florida. This bridge, completed in 1986, used innovative methods like balanced cantilever and overhead gantry cranes. It was erected over an active ocean navigation channel and under challenging ocean conditions. American Bridge also constructed the Tagus River Suspension Bridge rail deck addition in Lisbon, Portugal, a groundbreaking project involving the installation of new main cables on a busy bridge. This project set efficiency records in airspinning techniques.

In June 1996, American Bridge began work on a private island named Gorda Cay. This remote location, lacking infrastructure and even basic facilities, presented numerous logistical challenges, including transportation, housing, permits, and adverse weather conditions. Despite these hurdles, American Bridge successfully completed the project.

2000 to 2010

In 2002, American Bridge finished the Lions Gate Bridge Rehabilitation, which started in 1998. They faced a big challenge: replacing the whole top part of the bridge while keeping it open during the day. To do this, they came up with a special link structure and used an overhead gantry to move parts at night. They also made sure the weight on the cables stayed even and figured out how to change the cables and other parts.

They also rebuilt the Stanley Park Causeway and upgraded the north approach to the bridge to withstand earthquakes. They had to work closely with the Port of Vancouver because the bridge is over a busy waterway.

During this time, American Bridge built the biggest movable bridge, the Woodrow Wilson Bascule. It has eight parts and was started in 2003 and finished in 2008. American Bridge did all the mechanical work themselves.

They also worked on other big projects in the 2000s, like the Philadelphia Naval Lift Bridge, the Florida Avenue Lift Bridge in New Orleans, the Cumberland Lake truss bridge in Kentucky, and they fixed up the RFK Triborough and Macombs Dam bridges in New York City.

2010 to 2020

American Bridge was part of a joint venture that worked on the Queensferry Crossing project in Edinburgh, Scotland. This involved improving 9km of divided motorway, including building a 2,600m bridge over the Firth of Forth. The bridge has three towers and two long spans over water channels. It’s made of a mix of steel and concrete, and a special system of stays supports it. The team created six special gantries to help build the bridge. They used three big circular caissons to support the bridge’s foundations, going down 40m to reach solid rock. They also built the approach viaducts in two different ways.

In 2014, the American Bridge/Fluor Joint Venture finished the San Francisco/Oakland Bay Bridge Superstructure project. They had to build a temporary bridge to hold up the main bridge until they could put the cables in place. They also made a big crane to lift heavy parts and developed ways to move and position them. They had to come up with special methods to handle the cables and transfer the weight of the bridge onto them.

Also in 2014, American Bridge completed the world’s biggest observation wheel in Las Vegas, Nevada. This involved creating lots of new methods and equipment, like a system to support and move the wheel’s rim, a tower to support the wheel while it was being built, and a way to rotate the wheel as it was being assembled. They also had to figure out how to put the cabins on the wheel and handle other details. This project, like many others by American Bridge, showcased their ability to combine strong engineering with skilled ironworkers and experienced supervision.