News

Reaching the Summit

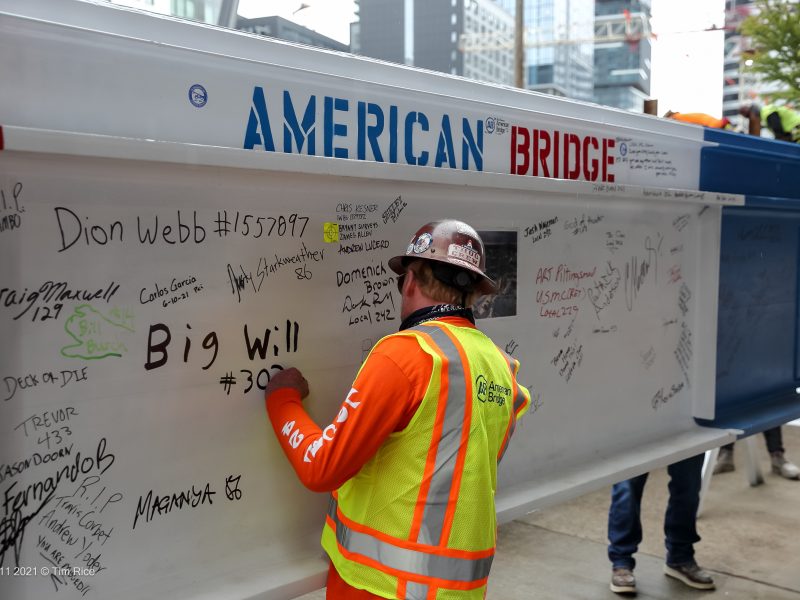

Reaching the Summit https://www.southlandholdings.com/wp-content/uploads/WSCC-May-28-2021-11-1024x683.jpg 1024 683 Southland Holdings Southland Holdings https://www.southlandholdings.com/wp-content/uploads/WSCC-May-28-2021-11-1024x683.jpgAfter a challenging climb to the top – the American Bridge Team at the Washington State Convention Center Addition celebrates a major milestone.

On Friday, June 11, a steel beam painted red, white, and blue, adorned with an evergreen tree and American flag was hoisted 195 feet into the clear, blue Seattle sky. This signaled the “topping out” of the Summit, a dramatic addition to the Washington State Convention Center. This long-standing tradition, commemorates the placement of the final piece of structural steel. The Summit building is the new 1.5 million square foot addition to the Washington State Convention Center and is targeted for a summer 2022 completion.

The construction of the Summit has been distinctive in many ways, including being built from east to west rather than bottom to top. This technique is known as billboarding, which allows multiple zones of construction to occur concurrently. The Summit is phased in five independent zones allowing trade work to start sooner than a conventional bottom up phasing. The advantage of the zone approach is that it compresses the schedule and allows the building to be enclosed earlier than otherwise possible, which is critical to completing the interior finishes.

Since breaking ground in 2018, crews have faced unique circumstances including adjusting to the new COVID-19 protocols. However, the AB team successfully navigated them through careful planning and safety measures, and has erected over 22,000 tons of structural steel to date. Project Manager James Thornton, recalls some of the innovative team accomplishments by AB’s in-house engineering and on-site crews.

- One of the unique features of the Summit is the monumental staircase which cantilevers over the southeast corner of the structure at Pine Street and Interstate 5. The design required a 111-foot-long, 50-foot-tall truss to be erected at Level 10 first, as it supports the rest of the cantilevered structure down to Level 3. AB engineering performed all of the phased erection analysis for this critical operation, which utilized a Manitowoc MLC300 crane. In February 2020, the team began erecting the 205-ton interstitial T-019 truss. This cantilever operation required the truss to be built on site and segmentally erected at night over I-5 during partial lane closures. This operation was complicated by the fact that AB was limited to performing impact work during short night durations due to noise ordinance restrictions after 10 pm.

- In October 2020, AB overcame an unforeseen complication when the project’s Manitowoc MLC300 crane mast sustained damage. Because the 386-ton crawler was an essential piece of equipment, and critical to the steel erection operation, finding a replacement on short notice was not feasible. AB engineers designed a stabilizing whaler system to transfer the load out of the main boom pendant bars. With the load transferred to the whaler system, the pendant bars were un-pinned from the mast, and the mast was removed and replaced while the 216.5-foot main boom and 138-foot luffing jib remained in the air. Through innovation, AB avoided considerable delay and mitigated having to demobilize and replace the 386-ton crane.

- On March 27, 2021, the AB team completed their heaviest pick, the T208 truss, weighing in at 188,363 pounds. This was accomplished as a single crane pick due to the the project team’s innovation to re-engineer the Zone 5 erection scheme. Originally, the scheme would have required the Zone 5 trusses to be erected in two pieces with the 386-ton crawler crane, which would have required supporting the bottom chord with temporary shoring posts. AB re-engineered the Zone 5 crane plan and designed a temporary trestle platform at street level to support a 660-ton Manitowoc 18000 Crawler Crane. With the added capacity, AB was able to ground assemble the entire 100-foot-long truss and erect it in just one pick. By improving the Zone 5 crane plan and erection sequence, AB was able to accelerate the project schedule by two months and mitigate delays to the project completion.

AB is a subcontractor to the Clark Construction and Lease Crutcher Lewis joint venture. AB’s scope includes the furnish and installation of structural steel, metal decking, pre-engineered metal stairs, buckling restrained braces, and miscellaneous metals.

More about the Summit

The new addition is located in downtown Seattle just one block northeast of the existing Washington State Convention Center. The Summit will consist of 15 levels adding approximately 248,450 square feet of total exhibit space, 59 meeting rooms, and a 58,000 square foot ballroom. The design of the building allows for natural light with major spaces connected vertically by two large atriums. In addition, the glass-enclosed stairs provide west-facing views of Pike Place Market and Puget Sound and the open-air terraces offer views of downtown Seattle.

- Post Tags:

- Project News

- Bridge Construction

- videos

- Posted In:

- News